|

Technical characteristics

|

Test Standard

|

Unit of Measure

|

PRI Products

MTRC Test |

|

UL 94 Vertical & Horizontal Burning Test

|

UL 94

|

V-O

|

|

|

Tensile

|

ASTM D638 IV

|

MPA

|

2893.03

|

|

Notched Izod

|

ASTM D256

|

mj

|

260.72

|

|

Density

|

ASTM D792

|

g/cm2

|

1.65

|

|

Water Absorbtion

|

ASTM D570

|

%

|

0.04

|

|

Surface Resistivity

|

ASTM D257

|

|

4.37

|

|

Technical characteristics

|

Test Standard

|

Unit of Measure

|

Material Rigid PVC

|

|

Specific Gravity

|

ASTM D792

|

g/cm3

|

1.41

|

|

Izod Impact Strength

|

ASTM D256

|

Kg-cm/cm

|

9

|

|

Heat Defection Temperature

|

ASTM D648

|

oc

|

80

|

|

Tensile Strenght

|

ASTM D648

|

Kgf/mm2

|

3.3

|

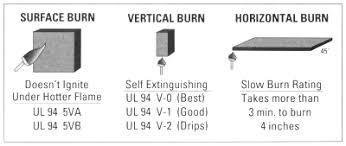

UL 94 Flammability Ratings Summary

| 5VA Surface Burn |

Burning stops within 60 seconds after five applications of five seconds each of a flame (larger than that used in Vertical Burn testing) to a test bar. Test specimens MAY NOT have a burn-through (no hole). This is the highest (most flame retardant) UL94 rating. |

| 5VB Surface Burn |

Burning stops within 60 seconds after five applications of five seconds each of a flame (larger than that used in Vertical Burn testing) to a test bar. Test specimens MAY HAVE a burn-through (a hole). |

| V-0 Vertical Burn |

Burning stops within 10 seconds after two applications of ten seconds each of a flame to a test bar. NO flaming drips are allowed. |

| V-1 Vertical Burn |

Burning stops within 60 seconds after two applications of ten seconds each of a flame to a test bar. NO flaming drips are allowed. |

| V-2 Vertical Burn |

Burning stops within 60 seconds after two applications of ten seconds each of a flame to a test bar Flaming drips ARE allowed. |

| H-B Horizontal Burn |

Slow horizontal burning on a 3mm thick specimen with a burning rate is less than 3"/min or stops burning before the 5" mark. H-B rated materials are considered "self-extinguishing". This is the lowest (least flame retardant) UL94 rating |

ตารางขนาดใส่สายไฟ ในรางขนาดต่างๆ

PRI Wiring Duct Full Cable Capacity Chart

|

Model

|

Telephone Cable

|

VAF

|

VFF

|

Single Cable

|

||||||||||

|

2C

|

4C

|

6C

|

2x1

|

2x1.5

|

2x2.5

|

2x4

|

2x6

|

2x0.5

|

2x1

|

2x1.5

|

2x2.5

|

Cat5E

|

RG-6

|

|

|

T1

|

2

|

2

|

1

|

NA.

|

NA.

|

NA.

|

NA.

|

NA.

|

1

|

1

|

NA.

|

NA.

|

NA.

|

NA.

|

|

T2

|

4

|

4

|

2

|

1

|

1

|

NA.

|

NA.

|

NA.

|

2

|

2

|

1

|

1

|

1

|

1

|

|

T3

|

8

|

8

|

5

|

2

|

2

|

1

|

1

|

1

|

6

|

4

|

4

|

3

|

2

|

2

|

|

T4

|

10

|

10

|

8

|

4

|

3

|

2

|

2

|

1

|

7

|

6

|

4

|

4

|

4

|

4

|

|

T5

|

12

|

12

|

10

|

5

|

4

|

3

|

3

|

2

|

9

|

6

|

6

|

5

|

5

|

5

|

|

T6

|

20

|

20

|

12

|

7

|

6

|

4

|

4

|

3

|

10

|

10

|

9

|

8

|

7

|

7

|

|

DD1

|

4

|

4

|

2

|

1

|

1

|

NA.

|

NA.

|

NA.

|

2

|

1

|

1

|

1

|

1

|

1

|

|

DD2

|

8

|

8

|

6

|

2

|

2

|

1

|

1

|

1

|

4

|

3

|

3

|

2

|

2

|

2

|

|

DD3

|

12

|

12

|

10

|

3

|

3

|

2

|

2

|

2

|

6

|

4

|

4

|

3

|

3

|

3

|

|

DD4

|

16

|

16

|

12

|

4

|

4

|

3

|

2

|

2

|

8

|

5

|

5

|

5

|

4

|

4

|

|

DD5

|

20

|

20

|

16

|

5

|

5

|

3

|

3

|

3

|

10

|

7

|

7

|

7

|

5

|

5

|

|

DD6

|

24

|

24

|

20

|

7

|

6

|

4

|

3

|

3

|

14

|

10

|

10

|

9

|

7

|

7

|

|

FD20

|

3

|

3

|

2

|

1

|

NA.

|

NA.

|

NA.

|

NA.

|

1

|

1

|

1

|

1

|

1

|

1

|

|

FD30

|

5

|

5

|

4

|

2

|

1

|

1

|

1

|

NA.

|

3

|

3

|

2

|

2

|

2

|

2

|

|

FD40

|

12

|

12

|

8

|

3

|

2

|

2

|

1

|

1

|

5

|

5

|

3

|

3

|

3

|

3

|

|

FD50

|

15

|

15

|

9

|

4

|

3

|

2

|

2

|

1

|

6

|

5

|

3

|

3

|

4

|

4

|

|

FD52

|

20

|

20

|

10

|

4

|

4

|

3

|

3

|

1

|

9

|

8

|

6

|

5

|

4

|

4

|

|

DD1225

|

12

|

12

|

5

|

3

|

2

|

2

|

1

|

1

|

6

|

4

|

4

|

3

|

3

|

3

|

|

DD1632

|

20

|

20

|

15

|

8

|

6

|

5

|

4

|

2

|

12

|

9

|

9

|

7

|

8

|

8

|

|

DD2040

|

30

|

30

|

24

|

12

|

10

|

7

|

6

|

4

|

20

|

10

|

10

|

12

|

10

|

9

|

2. ผลทดสอบท่อร้อยสายไฟ uPVC สีขาว ตรา PRI (uPVC White Conduit Testing Data)

มาตรฐานทดสอบ : BS-EN 50086-2-1

3. ผลทดสอบค่า IP มาตรฐานกันฝุ่น และน้ำ ตู้พลาสติกPRI (ํIP Standard Testing Data)

มาตรฐานทดสอบ : IEC60529

1. ตู้ HG1 (IP65)

2. ตู้กันฝน PR (IP44)

3. กล่องพลาสติกกันน้ำ PRI201 (IP54)

4. กล่องพลาสติกกันน้ำ PRI202 (IP54)

5. กล่องลอยกันน้ำ ML1 (IP54)

6 กล่องลอยกันน้ำ ML2 (IP54)